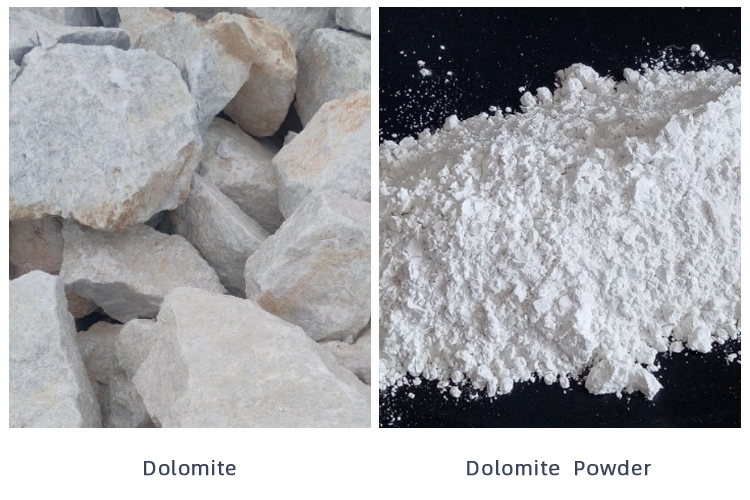

Dolomite

Dolomite is a vital calcium-magnesium resource primarily composed of magnesite and calcite, with minor amounts of clay minerals, chert, and occasionally gypsum, celestine, barite, pyrite, and organic matter. Boasting abundant reserves distributed across all provinces, proven dolomite deposits currently meet the demands of economic development. It serves as a high-quality raw material in industries such as metallurgy, chemical engineering, building materials, rubber manufacturing, and refractory materials.

Limestone

Limestone is a non-metallic mineral primarily composed of calcium carbonate (CaCO₃), with calcite and aragonite as main mineral components, and may contain impurities such as clay and dolomite. Physically, it appears as a white or grayish-white solid with a dense texture, but reacts vigorously with dilute acids to release carbon dioxide. Chemically, limestone decomposes into calcium oxide and carbon dioxide at high temperatures (approximately 825–1020℃), a property that forms the basis for quicklime production.

Marble

Marble is a common and versatile metamorphic rock primarily composed of calcium carbonate (typically accounting for over 50%), with minor amounts of magnesium carbonate, silicon dioxide, iron oxide, and other components. Additionally, it may contain minerals such as mica, bauxite, and garnet. It is mainly processed into various profiles and slabs for use as wall cladding, flooring, countertops, columns, and other architectural elements in buildings. It is also widely utilized as a material for monumental structures such as monuments, towers, and sculptures. Furthermore, its crushed stone and scrap materials can be used in the production of artificial stone, terrazzo, stone chips, and stone powder, or as fillers in industries including coatings, plastics, and rubber.

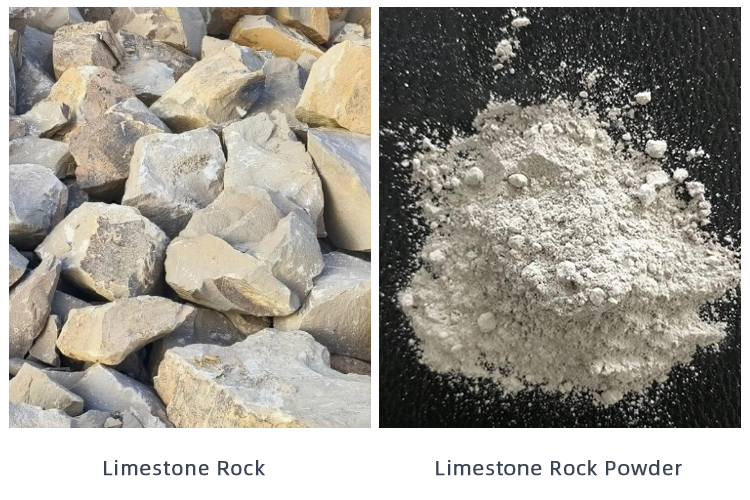

Limestone Rock

Limestone Rock is one of the most widely distributed and abundant sedimentary rocks on Earth, and also a core type of carbonate rock, playing a crucial role in geological evolution, industrial production, and ecological environments. Known as a "multi-functional industrial raw material," it boasts extensive applications across multiple fields and high utilization efficiency:

Construction and building materials sector; Industrial manufacturing sector: processed into stone powder for use as fillers in coatings, plastics, and rubber, or as whitening and thickening agents in papermaking and toothpaste production.

Non-Metallic Mineral Grinding Project

To meet the fineness requirements of the aforementioned ores across various fields, Zenith has developed a range of non-metallic mineral grinding equipment, mainly including the LM Vertical Mill and MTW European Trapezium Mill for fine powder (80–400 mesh).

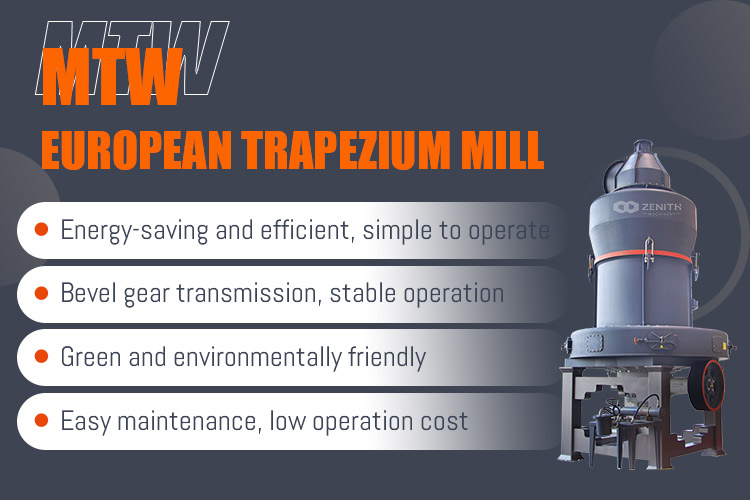

MTW European Trapezium Mill Dolomite Grinding Project

Processing Material: Dolomite

Finished Product Fineness: 250 mesh, 280 mesh

Equipment Used: MTW European Trapezium Mill

The main equipment of this project is the Zenith MTW European Trapezium Mill. The entire production line can accurately complete the integrated grinding process of dolomite, covering feeding, conveying, grinding, air classification, powder collection, dust removal, and packaging. It improves overall efficiency, reduces long-term operating costs for customers, and serves as a cost-effective choice that balances high performance and sustainability.

LM Vertical Mill Limestone Grinding Project

Processing Material: Limestone

Equipment Used: LM Vertical Roller Mill

Country: Kyrgyzstan

This project adopts Zenith's LM Vertical Roller Mill. During the production process, the equipment can achieve continuous and stable powder output, precisely control the finished product particle size, and ensure the purity and activity of limestone powder. With the characteristics of low energy consumption and easy maintenance, it reduces the unit powder consumption, supports the long-term stable operation of the production line, and helps enterprises maximize production efficiency.

MTW European Trapezium Mill Marble Grinding Project

Processing Material: Marble

Finished Product Application: Chemical Coatings

Equipment Used: MTW European Trapezium Mill

Country: Uzbekistan

The equipment adopted in this project is Zenith's MTW European Trapezium Mill. With a rational layout and planning of the entire production line, the MTW European-Style Mill outperforms other equipment in energy efficiency and boasts excellent environmental performance. Featuring ultra-high stability and strong continuous operation capacity, it safely and efficiently completes the grinding tasks, providing solid support for the smooth progress of the project. It has won the trust and recognition of customers with the advantages of "higher production efficiency, smarter control, and greener operation."

LM Vertical Mill Limestone Rock Grinding Project

Processing Material: Limestone Rock

Equipment Used: LM Vertical Mill

This project is an efficient and environmentally friendly non-metallic mineral processing project built around Zenith's LM Vertical Mill as the core equipment, specifically designed to meet the refined grinding requirements of limestone raw materials. Leveraging the core advantage of "simultaneous grinding and drying," the LM Vertical Mill can efficiently process high-moisture limestone raw materials, significantly shortening the processing cycle. Meanwhile, the equipment adopts a closed-loop circulation system, low-energy-consumption grinding technology, and is equipped with a dust recovery device, achieving energy conservation, environmental protection, and zero-pollution dust emission—fully aligning with the development requirements of green industry.

Zenith LM Vertical Roller Mill

Zenith LM Vertical Roller Mill features a scientific and rational design principle, integrating grinding, drying, and powder classification into a single unit. It effectively addresses the common challenges of low output, high energy consumption, and high maintenance costs associated with industrial grinding mills currently available on the market. Boasting stable product performance, smooth operation, high efficiency, large output, and a high degree of automation, this mill stands out as a superior solution for industrial grinding applications.

Zenith MTW European Trapezium Grinding Mill

Zenith MTW European Trapezium Grinding Mill adopts innovative grinding technology, achieving breakthroughs in multiple aspects including the transmission system, lubrication system, air duct design, roller and ring structure, finished product particle size control and classification system, air intake volute design, and intelligent control system. It is highly compatible with non-metallic mineral grinding requirements, truly realizing efficient, stable, energy-saving, and intelligent powder production.

Zenith Provides Comprehensive Grinding Equipment Solutions

Zenith offers full-set grinding equipment solutions, continuously advancing technological innovation and developing a series of high-efficiency, energy-saving, and environmentally friendly grinding equipment. These innovations enhance the efficiency and quality of non-metallic mineral grinding, empowering the industry to move toward high-endization and intelligence.