Language

Language

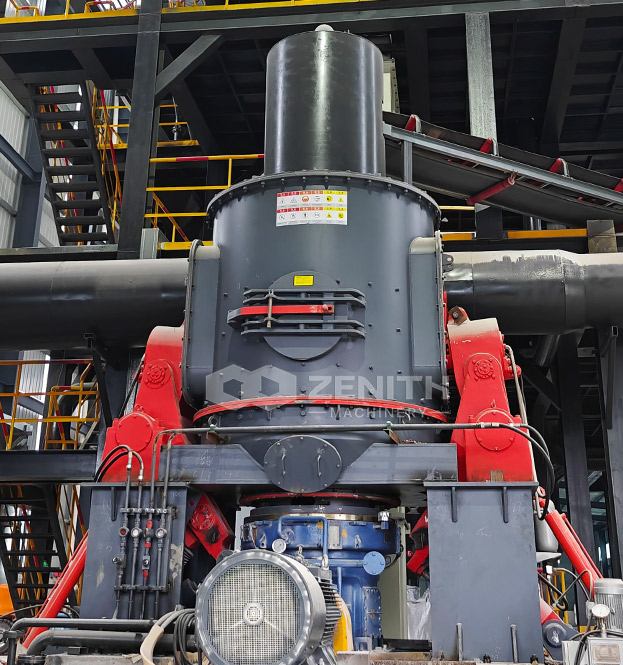

LM-Y series vertical pre-grinding mill is an advanced grinding equipment based on the technology of LM series vertical mill, extensively absorbing advanced technologies at home and abroad, and combined with the production processes of the cement industry, non-metallic minerals and other fields.

LM-Y series vertical pre-grinding mill is widely used in industries such as cement, electric power, metallurgy, chemical industry, non-metallic minerals, industrial milling stations, etc., such as pre-grinding of cement clinker, ceramic raw materials and other non-metallic mineral coarse powder preparation, sand making, etc.

Capacity: 6-330T/H

Input Size: <20mm

Output Size: <5mm

Product Data Download

Product Data Download

It integrates sand making and grinding, which can be used for making sand and can also be used as grinding equipment.

For making powder, the content of coarse and fine powder can be controlled and the quality is good. For making sand, the particle size of the sand is well graded and the particle shape is good.

The core components are made of hard-wearing material to improve its performance and save cost.

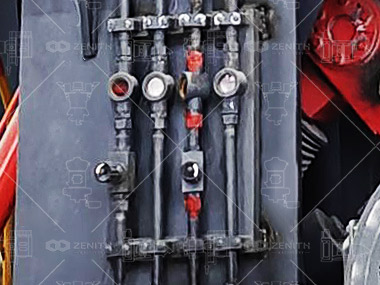

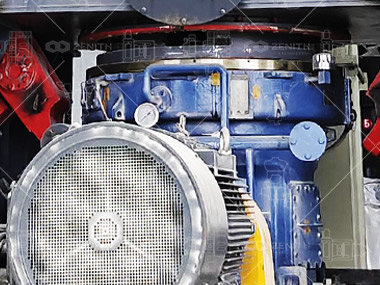

It adopts hydraulic adjustment system and is suitable for materials of various strengths and hardness. The grinding roller can be flipped outside the machine, making it easy and quick to replace the roller sleeve and liner.

The main motor drives the grinding plate via the reducer, causing material to fall from the discharge port to the center of the grinding disc. Centrifugal force moves the material uniformly from the center to the edge, where large pieces are crushed and fine particles form a bed for inter-particle crushing. The crushed material is thrown out of the grinding disc, falls into the lower cavity, and is scraped to the discharge port by scrapers. It is then transported to sorting equipment, where coarse material is returned for re-grinding, and fine material is collected as finished product by the powder collector.

Fill your requirements in the following form, we will contact you as soon as possible.