Language

Language

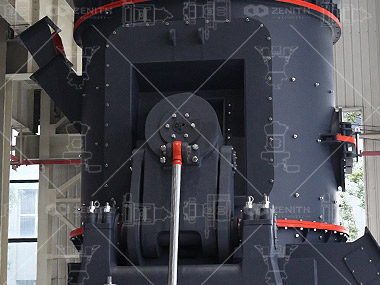

LM series vertical roller mills are a excellent grinding equipment, which have the capacity of 24hours constant running. Because of this automatic operation, this VRMs are popular in the condition, which needs easy monitor, large capaity, constant running, stable product quality, like large mineral powder plant, cement plant, GGBS powder plant, coal grinding plant, etc.

Capacity: 3-170T/H

Input Size: 0-50mm

Output Size: 80-600mesh

Product Data Download

Product Data Download

LM Vertical Grinding Mill can effectively control product size, chemical composition and iron content, and ensure the purity and whiteness of finished materials.

LM Vertical Grinding Mill adopts a compact integrated design, which covers an area of about 50% of the ball mill system, and can be arranged in the open air with less comprehensive investment.

LM Vertical Grinding Mill is equipped with an automatic control system, which can realize free switching between remote control and local control. It is easy to operate and has low labor cost.

LM Vertical Grinding Mill is sealed and operates under negative pressure, characterized by no dust spillover, small vibration, low noise, and more eco-friendly production.

The main motor drives the grinding disc via the reducer, with hot air entering the chamber. Material falls to the disc's center, moves outward by centrifugal force, and is crushed by rollers, forming a material bed for inter-particle crushing. Crushed material moves to the disc's edge, carried by airflow; larger particles return for further grinding. Airflow passes through a separator, where coarse particles are returned, and fine powder is collected. Iron debris falls into the lower cavity, scraped to the discharge port, and removed.

Fill your requirements in the following form, we will contact you as soon as possible.