Language

Language

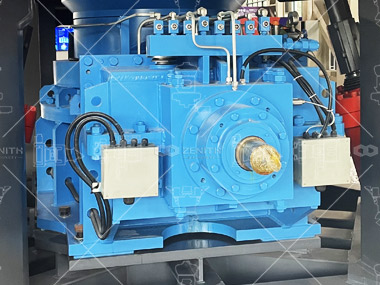

As a new type of ultrafine grinding equipment, the LUM ultrafine vertical mill integrates powder grinding, separation and transportation. With years’ experience in mill production, the LUM ultrafine vertical roller mill are designed by our company, basing on vertical mills, we introduce Taiwan’s grinding roller technology and Germany powder separating technology. As a professional medium and high-end processing equipment in plastic master batch, PVC, artificial stone, electric cable, non-woven fabrics and other industries,LUM Series LUM Ultrafine Vertical Mill is mainly used for the ultrafine grinding of calcite, marble, limestone, talc, dolomite, barite, kaolin, wollastonite, gypsum, feldspar, pyrophylite and other non-metallic mineral ores.

Capacity: 1.6-15T/H

Input Size: 0-10mm

Output Size: 325-2500mesh

Product Data Download

Product Data Download

LUM Ultrafine Vertical Grinding Mill can effectively control the product size, chemical composition and iron content, and ensure the purity and whiteness of finished materials.

LUM Grinding Mill can accurately control grinding pressure, speed and other parameters. Compared with ordinary mills, the energy consumption is reduced by 30%-50%.

LUM Ultrafine Vertical Grinding Mill adopts reversible structure. With the hydraulic adjustment system, vulnerable parts can be easily and quickly repaired and replaced.

LUM Ultrafine Vertical Grinding Mill is sealed and operates under negative pressure, characterized by no dust spillover, small vibration of equipment, low noise, and more environmentally friendly production.

Material falls into the center of the grinding disc via the spiral feeder. The main motor drives the disc, creating centrifugal force to spread the material. Crushed by rollers, large pieces break down, and small particles form a material bed for inter-particle crushing. Crushed material moves to the disc's edge, carried by airflow into the powder selector for classification. Unqualified powder returns for re-grinding, while qualified powder enters the dust collector as finished product. Iron impurities fall into the lower cavity, scraped to the slag outlet, and discharged.

Fill your requirements in the following form, we will contact you as soon as possible.