Neodymium-iron-boron (NdFeB), hailed as a new magnetic functional material known as the "King of Magnets", generates a large amount of debris and leftover materials during production and processing. Coupled with residual raw materials from the compression molding and sintering processes, these are collectively referred to as NdFeB waste in the industry. Compared with extracting rare earth elements from ores, recovering valuable elements such as rare earths and iron from such "waste" has irreplaceable advantages: shorter production processes and lower costs. It not only complies with national rare earth resource management policies but also contributes to environmental protection.

Recovering NdFeB waste can extract various valuable products such as neodymium oxide, terbium oxide, dysprosium oxide, and cobalt oxide. However, the recycling and utilization of such industrial waste impose extremely high requirements on the grinding accuracy, production capacity, and environmental performance of powder grinding equipment.

Shanghai Zenith is powder grinding equipment efficiently processes waste with excellent performance, becoming the core equipment support for the recycling of rare earth resources. It actively responds to national industrial policies, helps enterprises realize the value transformation of "turning waste into treasure", and can be called an equipment pioneer in this field.

This time, Shanghai Zenith made an appearance at the site of a large-scale NdFeB recycled material utilization project in Inner Mongolia. Since its commissioning, the production line has operated stably, and the output has exceeded expectations. Behind this achievement, there is not only the solid support of Shanghai Zenith's high-quality powder grinding equipment and advanced technology, but also the indispensable guarantee of its comprehensive after-sales service and the full escort of the professional maintenance team.

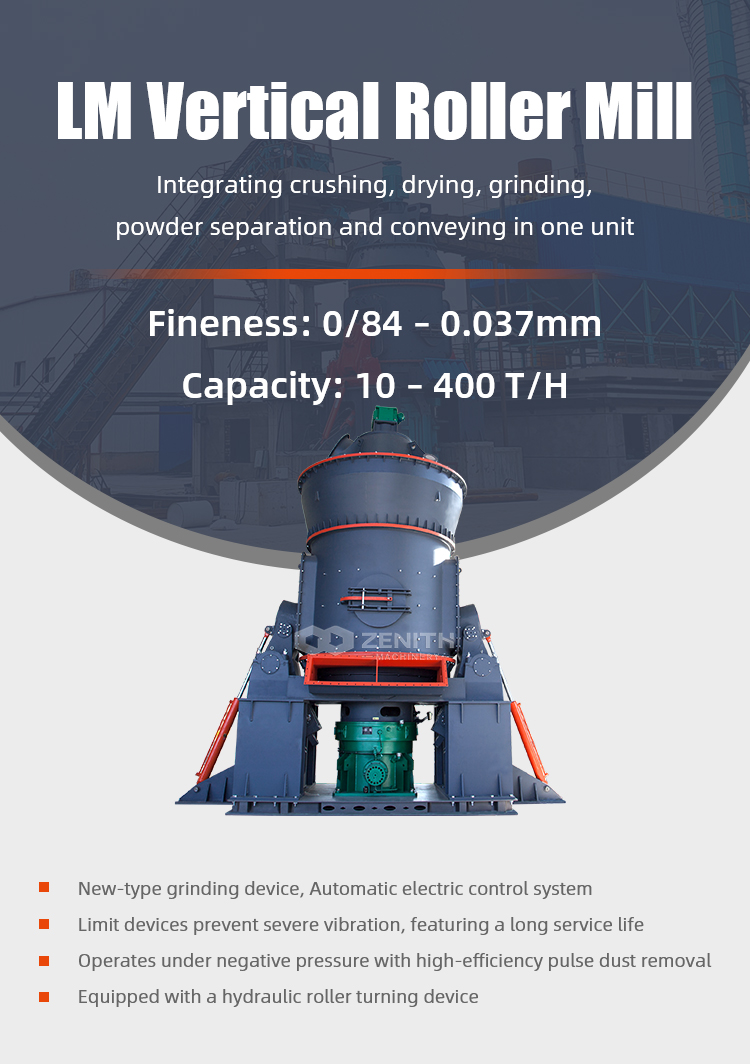

Material: Recycled NdFeB Material

Fineness: 200 mesh

Equipment: Shanghai Zenith LM Vertical Roller Mill

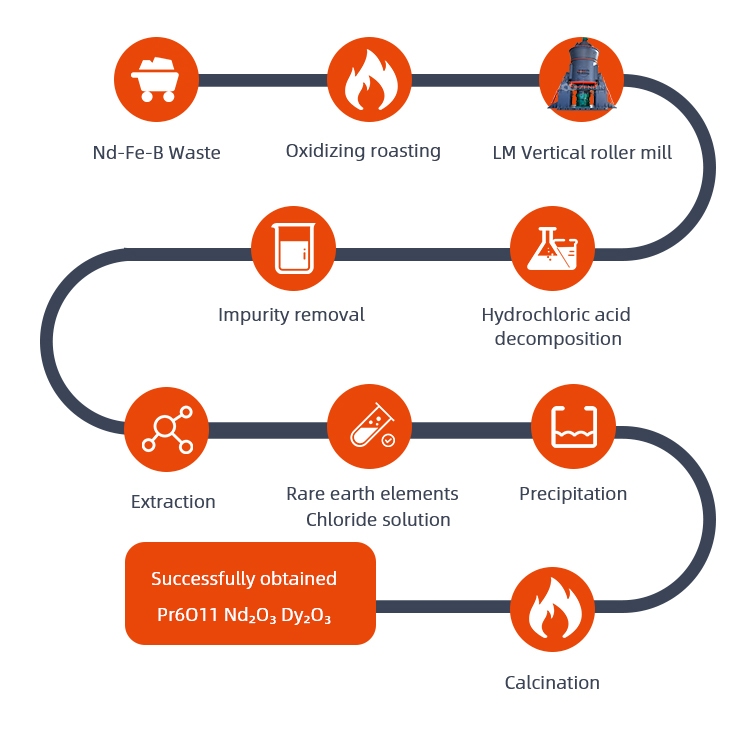

This project integrates intelligent batching, multi-layer furnace sintering process and Shanghai Zenith's vertical roller mill crushing system, ultimately producing mixed rare earth oxides. The entire production system features high efficiency, energy saving and environmental protection, with a high level of automation.

Shanghai Zenith has always adhered to the original aspiration of service and is committed to creating a one-stop service experience of "worry-free, assured and peace of mind" for customers. Its service team provides multi-dimensional professional support. By guiding operators to proficiently master the use skills of the intelligent control system, it converts complex operations into convenient processes and helps customers quickly improve operation and maintenance efficiency.

NdFeB waste can be called a valuable secondary rare earth resource, but the composition of waste from different sources varies, which imposes extremely high requirements on equipment in the powder grinding and preparation link. However, NdFeB powder with stable purity, concentrated particle size distribution and good fluidity is a key prerequisite for producing high-performance magnetic rare earth products.

Shanghai Zenith LM Vertical Roller Mill accurately meets the core needs of NdFeB powder grinding. It is a high-quality equipment integrated with modern powder grinding technology and with independent intellectual property rights. The equipment integrates powder grinding, drying, powder selection and conveying functions. It can not only achieve high product purity and precise particle size control, but also has the advantages of energy saving and consumption reduction, high intelligence level, and 24-hour continuous and stable operation, making it the preferred equipment in the field of industrial recycling of NdFeB waste.