Driven by the upgrading demands of downstream industries such as building materials, plastics, coatings and papermaking, the calcium carbonate grinding industry is undergoing a transformation from "extensive processing" to "refinement, high efficiency and green development". The pain points of traditional grinding equipment, including high energy consumption, unstable fineness and cumbersome maintenance, can no longer meet the needs of modern production — and a set of grinding solutions featuring intelligent control, high output, energy conservation, environmental friendliness and wear resistance has become the core competitiveness for enterprises to reduce costs, improve efficiency and seize market share.

Industry's pressing demands drive technological upgrading: How to select the right grinding equipment?

As the world’s most widely used inorganic filler, the grinding fineness of calcium carbonate directly determines the quality of end products:

The plastics industry requires fine powder of 325–2500 mesh to enhance the toughness and glossiness of products;

The coatings industry imposes stringent requirements on the dispersibility and whiteness of ultra-fine powder above 1250 mesh;

The papermaking industry needs to balance output and energy consumption to control production costs.

Traditional ball mills and Raymond mills suffer from drawbacks such as low production capacity, high energy consumption and significant fineness fluctuations. In contrast, the new-generation MTW European Trapezium Grinding Mill has become the mainstream choice in the industry by virtue of the following core advantages:

Drawing on nearly 40 years of R&D and manufacturing experience, Zenith has launched the MTW European Trapezium Grinding Mill tailored for calcium carbonate grinding. Boasting multiple core advantages and adopting innovative grinding technology, the equipment has achieved breakthroughs in various aspects including the transmission system, lubrication system, air duct design, roller and ring structure, finished product particle size control and classification system, air inlet volute design as well as intelligent control system, truly realizing efficient, stable, energy-saving and intelligent powder processing.

MTW European Version Trapezium Grinding Mill: The Key Engine for Calcium Carbonate Grinding

Technology Iteration, Mature and Stable Equipment

With nearly 40 years of mill manufacturing experience, Zenith has rolled out four generations of grinding mill upgrades, boasting leading-edge technology and stable equipment operation.

Special Grinding Design for High Efficiency

The curved shovel design is adopted to expand the material grinding area and improve grinding efficiency.

Bevel Gear Integrated Drive for Lower Energy Consumption

The integrated bevel gear drive and resistance-free air inlet volute design ensure better material fluidity and lower energy consumption.

Thin Oil Lubrication to Extend Bearing Service Life

Both the main shaft transmission system and the fan transmission system adopt thin oil lubrication. Compared with the traditional grease lubrication, it features smaller lubrication resistance and lower oil temperature, which can effectively extend the service life of bearings.

New Variable-Frequency Classifier for High Precision of Finished Products

A new suspended cage classifier with variable-frequency control is adopted. The fineness is adjustable and controllable, meeting the requirements of various particle size specifications.

Economical Investment, Green and Environmentally Friendly

It covers a small floor area with a simple structural layout. The entire system operates under negative pressure without dust leakage, complying with the latest national environmental protection standards.

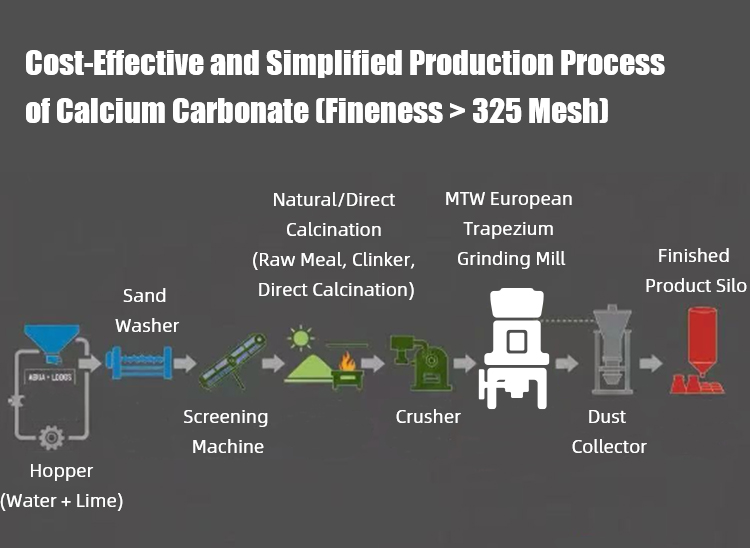

MTW European Version Trapezium Grinding Mill Calcium Carbonate Powder Processing Flow

Future Trends: Intelligence and Green Development as the Core Track

With the advancement of the "dual carbon" policy and the upgrading of downstream industries, selecting a grinding equipment that matches one’s production capacity and product requirements can not only reduce production costs, but also seize the discourse power in the high-end market! If you are looking for a calcium carbonate grinding solution, you may focus on the three core indicators of Zenith MTW European Trapezium Grinding Mill: controllable fineness, low energy consumption level and low maintenance cost, and let technological upgrading empower your enterprise development!