Backed by its core technological breakthroughs and rich project service experience, Zenith has custom-developed the LM280M Vertical Mill to meet the needs of the customer's 400,000-ton annual output prebaked anode project. This system not only overcomes the industry challenge that a single calcined coke grinding equipment is difficult to achieve large production capacity, but also effectively drives the local aluminum industry into a new stage of high-quality upgrading through green and intelligent solutions.

This project is a 400,000-ton annual output prebaked anode project and an important supporting project for the green hydropower aluminum integration project. Its core idea is to make full use of the local abundant hydropower resources, focus on the goal of "building a zero-carbon aluminum industry ecological closed loop", and construct a vertical green industrial chain system from anode carbon preparation to electrolytic aluminum production.

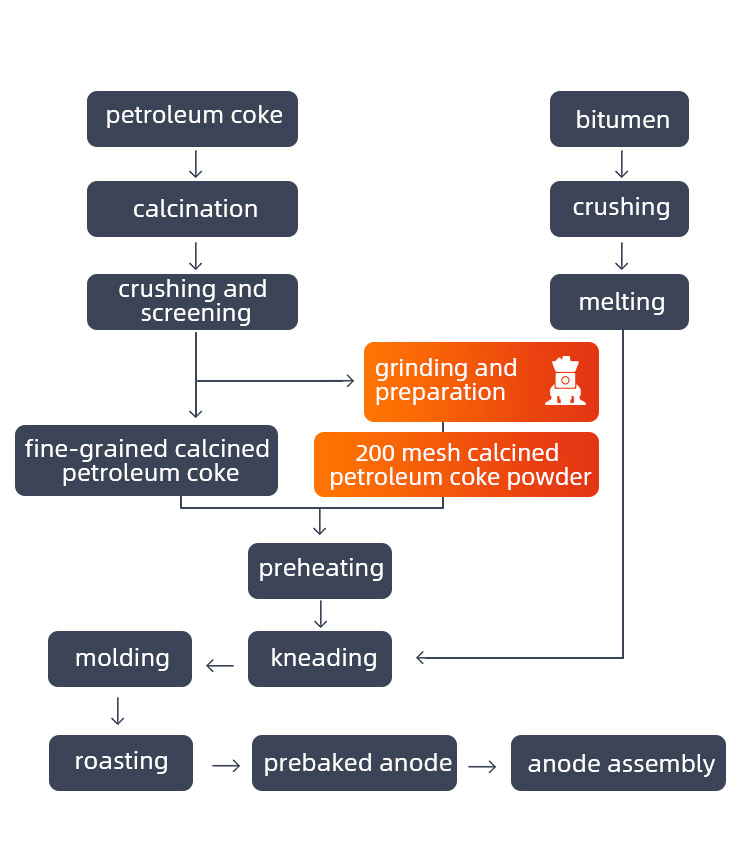

Material: Calcined Coke

Fineness: 200 Mesh

Application: Prebaked Anodes

Equipment: LM Vertical Grinding Mill

The customer clearly listed "green, efficient, and stable" as the core criteria for equipment selection. Relying on a large number of successful cases accumulated in the petroleum coke field and customizable exclusive design solutions, Zenith ultimately met the customer's needs and won the cooperation opportunity with the core advantages of "better whole-life cycle cost and faster operation and maintenance response".

As the core supplier of this project, Zenith provides a complete set of grinding system solutions. Its services cover the entire process, from design, material selection, and manufacturing to operation and maintenance support, installation guidance, commissioning, acceptance, and personnel training. The scope of its services is clearly defined as starting from the pressure-resistant weighing coal feeder under the pre-mill silo and ending at the discharge port of the screw conveyor at the lower end of the pulse dust collector, ultimately achieving a "turnkey" delivery.

Focusing on the customer's needs and addressing the three major process difficulties in the project regarding equipment configuration, environmental emission, and finished product purity, Zenith quickly established a dedicated technical team. Through targeted research and development, the team achieved breakthroughs in each difficulty one by one:

Hardware Configuration: Core components of the LM Vertical Grinding Mill, such as grinding rollers and bearings, all adopt products from internationally renowned brands. This configuration ensures the equipment’s ability to operate continuously for a long time from the source and effectively avoids fault shutdowns.

Environmental Compliance: The project location enforces strict ultra-low emission standards for industrial waste gas. To this end, it is necessary to simultaneously deploy treatment systems for dust-containing exhaust gas and volatile organic compounds (VOCs) to ensure emissions fully meet local requirements.

Purity Control: By equipping an online particle size detector, real-time monitoring and data feedback of the finished product’s fineness can be achieved. This measure enables precise control of finished product quality and ensures the fineness of each batch of products remains stable.

Currently, the equipment has completed commissioning and entered the stable operation phase. Both the equipment operation data and finished product parameters fully meet the planned expected standards, and the customer has highly praised the equipment performance and process adaptability. Among them, the LM Vertical Grinding Mill has become an indispensable core equipment in the customer's production line, relying on its stable operation performance and efficient output capacity.

Facing the profound changes in the carbon industry in the future, Shanghai Zenith will take "craftsmanship manufacturing and green development" as its core guideline. By integrating the whole-life cycle service capabilities of "equipment + service + data", it will continuously launch green solutions made by Zenith Intelligent Manufacturing, help the global carbon industry achieve sustainable development, and earnestly fulfill the responsibilities and obligations of a Chinese enterprise.