In recent years, with the rapid rise of the global new energy industry and the continuous advancement of industrialization, the market demand for aluminum carbon materials—core materials in electrolytic aluminum production—has been steadily climbing.

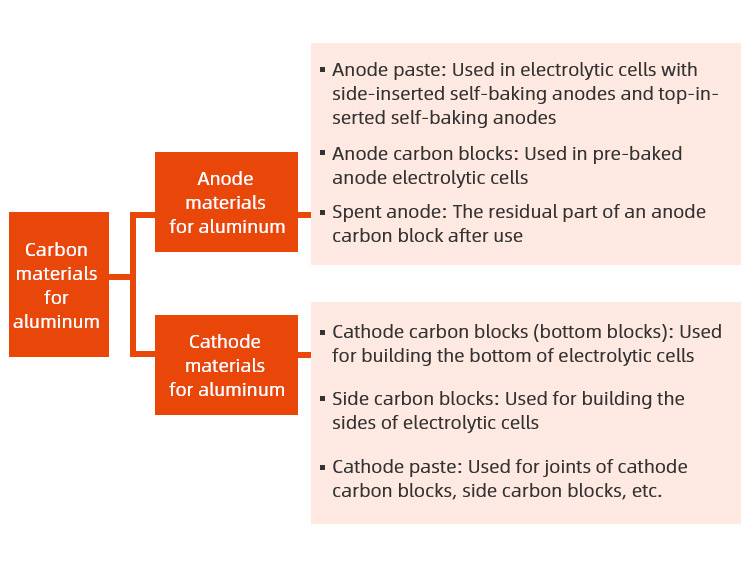

Aluminum carbon materials are regarded as a crucial cornerstone of the aluminum electrolysis industry. Based on their positions and functional differences within electrolytic cells, they can be divided into two major categories: anode materials and cathode materials.

Pre-baked anodes are typical representatives of anode materials for aluminum carbon. They are carbon blocks with stable geometric shapes, made by roasting aggregates such as petroleum coke and pitch coke, with coal tar pitch as a binder. Pre-baked anodes not only act as conductors but also participate in electrochemical reactions, during which they are consumed. Therefore, the quality of pre-baked anodes has a significant impact on the quality of primary aluminum.

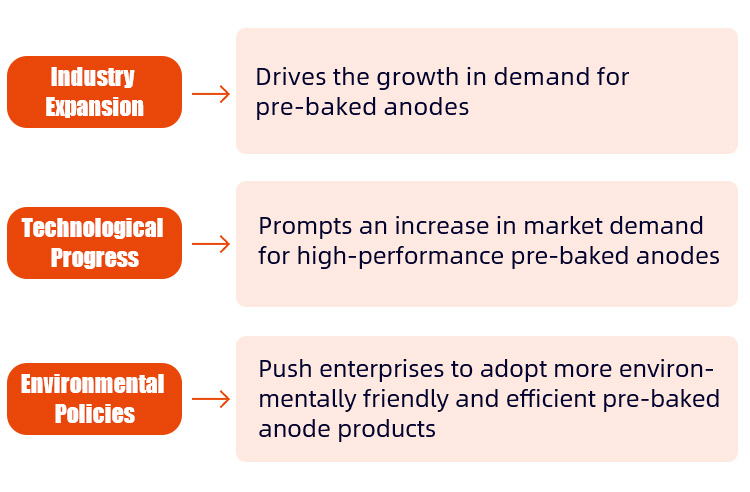

Driven by multiple factors, the global demand for pre-baked anodes has shown a steady growth trend

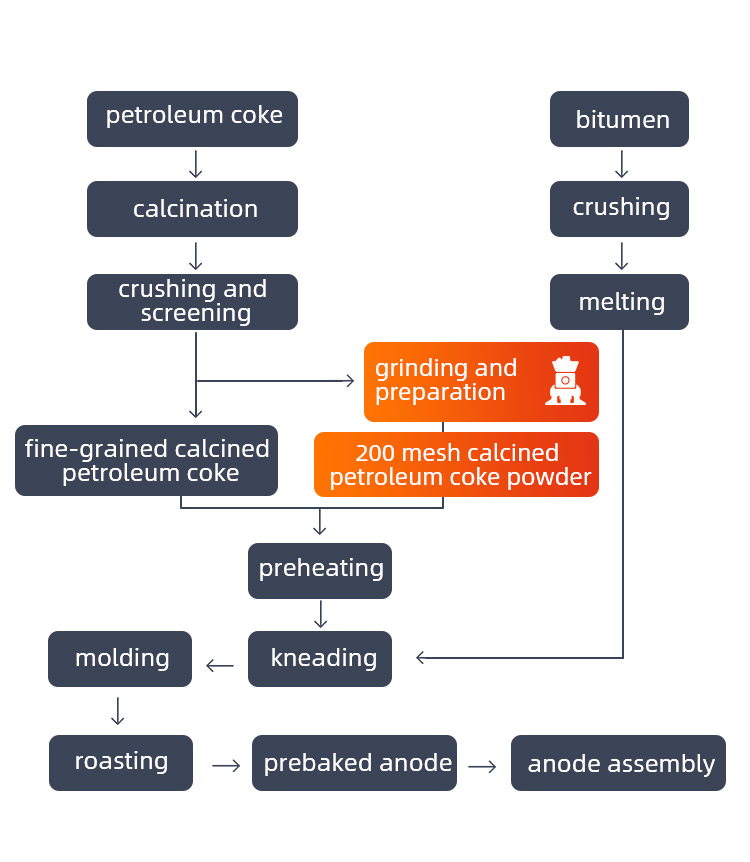

Preparation process of carbon anodes for aluminum

Development trends of carbon grinding processes for aluminum

High efficiency and energy saving

Uniform fineness

Stable purity

Stability and reliability

Clean and environmentally friendly

Intelligent control

MTW European trapezium grinding mill

Fineness:80-325 mesh

Capacity:3-50 t/h

Mature and stable equipment

Nearly 40 years of mill manufacturing experience, with four generations of mill upgrades

High grinding efficiency

Adopting a curved shovel design to increase the material grinding area and improve grinding efficiency

Bevel gear integral transmission

Employing bevel gear integral transmission and a non-resistance air intake volute design, resulting in better material fluidity and lower energy consumption

Thin oil lubrication

Low resistance, low oil temperature, oil change interval as long as 4 months, and reduced maintenance frequency

LM Vertical Mill

Fineness:80-400 mesh

Capacity:10-340 t/h

Multifunctional integration

Integrating crushing, grinding, drying, powder selection and conveying in one

High-efficiency grinding

With a special structural design of grinding rollers and disc, the grinding rollers are equipped with a hydraulic automatic pressurizing device, featuring a larger grinding area and high grinding efficiency

Intelligent control system

Equipped with an automatic control system, it enables simple and flexible operation, reducing operation and maintenance costs

Stable environmental performance

The whole system is sealed and operates under negative pressure, with no dust overflow