What are non-metallic minerals?

Non-metallic minerals refer to mineral resources that consist of non-metallic elements with economic utilization value, and can be directly developed and utilized by virtue of the chemical properties, physical attributes, and technological performance of minerals and rocks.

Overview of Non-Metallic Minerals

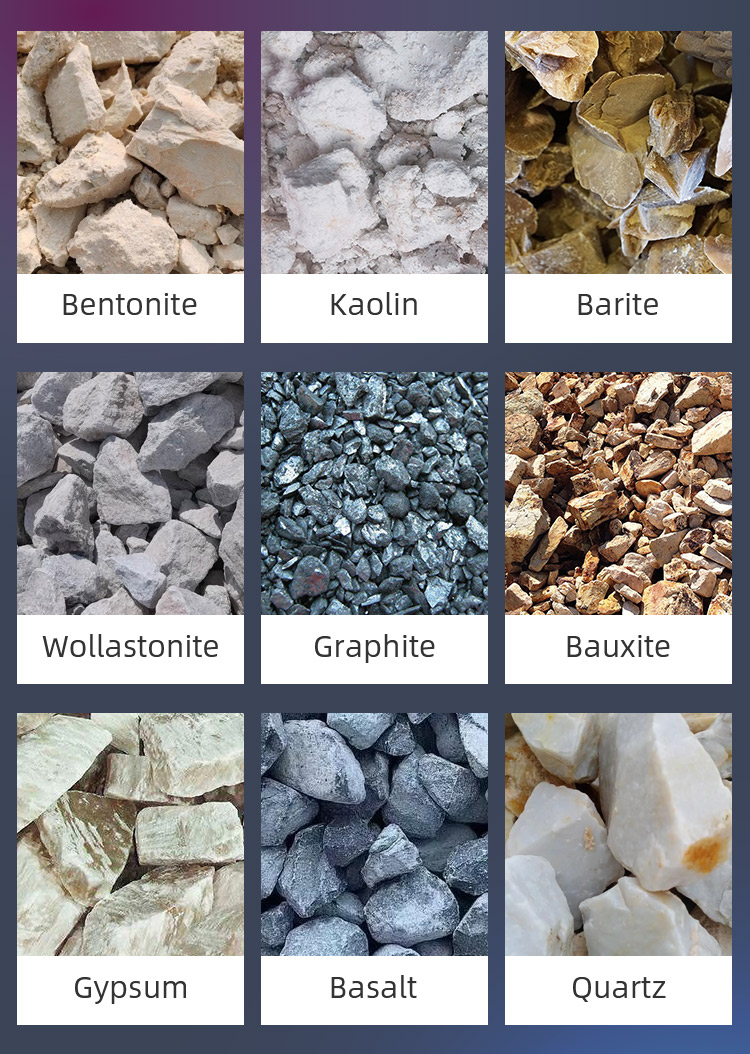

China has proven reserves of 88 types of non-metallic minerals, covering multiple categories such as native elements, oxides, halides, and oxysalts, forming a resource system with complete varieties and comprehensive supporting capabilities. From common minerals like limestone and gypsum to quartz and graphite required in high-end fields, all have the potential for large-scale development.

Classification and Applications of Non-Metallic Minerals

Due to the diversity of their origins, the complexity of their chemical compositions, and the overlapping nature of their uses, the classification system of non-metallic minerals exhibits multi-dimensional characteristics. Currently, they are mainly classified based on three principles: geological origin, product value, and industrial applications.

Chemical Fuels

Rock salt, Glauber's salt, trona, alunite, native sulfur, apatite, barite, celestite, fluorite, etc.

Optical Raw Materials

Iceland spar, optical gypsum, calcite, crystal, optical quartz, optical fluorite, etc.

Electronics and Electric Power

Graphite, mica, quartz, crystal, tourmaline, rutile, etc.

Agricultural Fertilizers and Pesticides

Apatite, potash, potassium feldspar, Glauber's salt, gypsum, kaolin, dickite, bentonite, etc.

Adsorption and Filter Aids

Zeolite, kaolin, diatomite, sepiolite, attapulgite, dickite, bentonite, saponite, perlite, etc.

Thermal Insulation

Asbestos, gypsum, graphite, vermiculite, diatomite, sepiolite, perlite, basalt, diabase, etc.

Petroleum Industry

Barite, ilmenite, bentonite, attapulgite, sepiolite, montmorillonite, quartz sand, kaolin, etc.

Building Materials

Asbestos, gypsum, granite, marble, quartzite, limestone, diatomite, sandstone, clay, etc.

Glass

Quartz sand and quartzite, feldspar, nepheline syenite, vein quartz, etc.

Ceramics and Refractories

Kaolin, wollastonite, talc, quartz, feldspar, andalusite, kyanite, sillimanite, pyrophyllite, tourmaline, diopside, graphite, magnesite, dolomite, bauxite, argil, fluorite, feldspar, borax, etc.

Fillers and Pigments

Calcite, marble, chalk, talc, pyrophyllite, graphite, kaolin, mica, wollastonite, bentonite, saponite, sepiolite, attapulgite, feldspar, barite, gypsum, quartz, etc.

Grinding and Deep Processing of Non-Metallic Minerals

With the global industrial upgrading, the application of non-metallic minerals has shifted from extensive raw material supply to refined material services, and grinding and deep processing has become a core link in unlocking their value potential. This process, through crushing, grinding, classification and other processing techniques on raw ores, endows mineral powders with specific particle size distributions, purity levels, and functional properties to meet the stringent requirements of high-end manufacturing, green building materials, new energy and other fields.

High-Quality Grinding Mills Facilitate Powder Preparation

As a world-leading supplier of grinding equipment, Zenith, relying on over 30 years of technical accumulation, has launched a variety of efficient, intelligent and environmentally friendly grinding equipment tailored to the needs of non-metallic mineral deep processing. Based on its rich application experience, it also provides full-process solutions from process design to equipment selection.

MTW European Trapezium Grinding Mill

Applicable Fields: Fine grinding of medium-hard materials such as gangue, petroleum coke, and barite, especially suitable for industries like environmental protection desulfurization, carbon, and metallurgy.

Technical Advantages:

The curved shovel design expands the grinding area, and the adoption of a resistance-free air inlet volute design reduces energy consumption, achieving energy-saving effects.

The high-efficiency cage-type powder separator enables flexible adjustment of fineness from 80 to 325 meshes, effectively avoiding the "coarse powder leakage" phenomenon and ensuring stable and reliable finished product quality.

The thin oil lubrication system extends bearing service life, ensures smooth operation, and reduces maintenance costs.

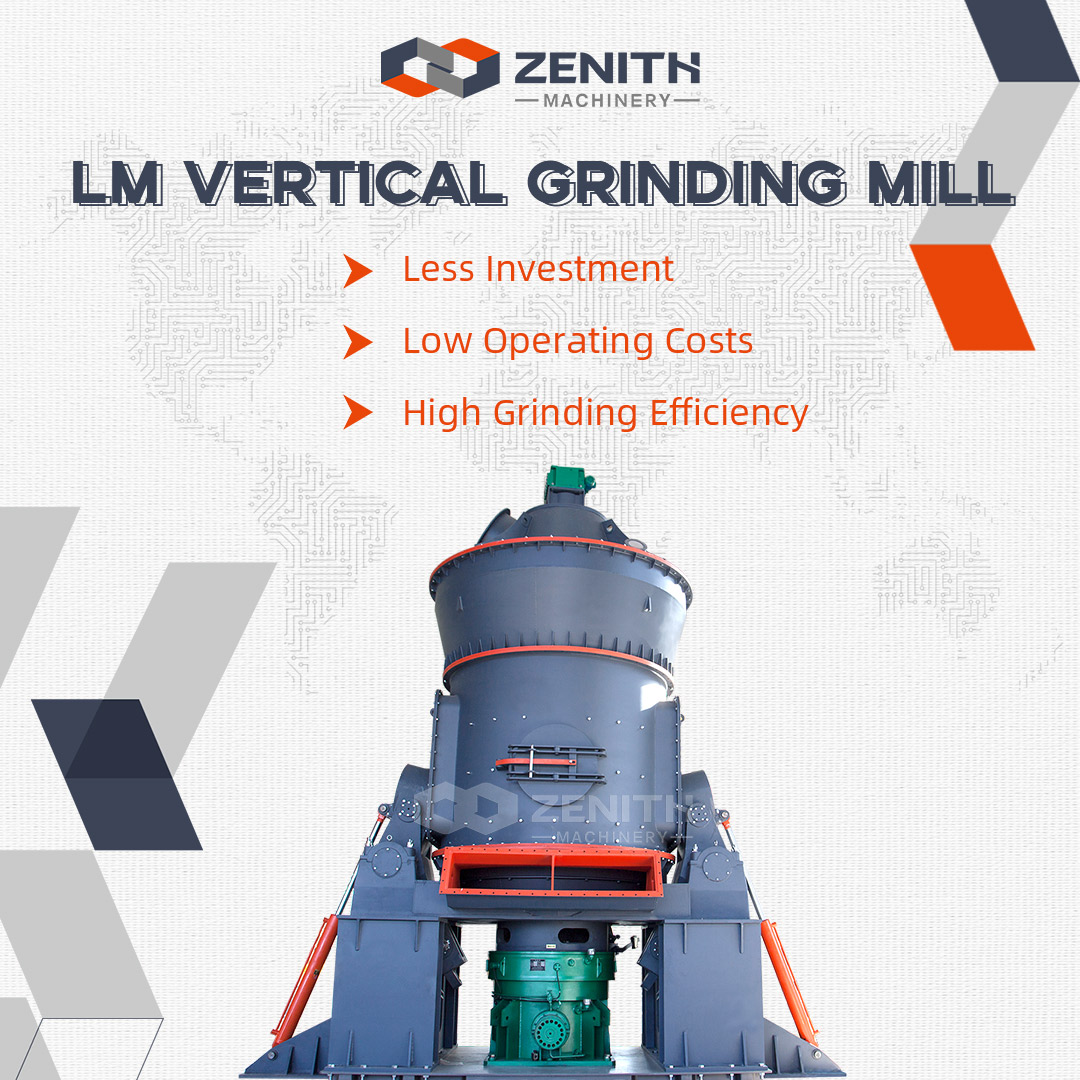

LM Vertical Roller Mill

Applicable Fields: Specifically designed for industries such as metallurgy, electric power, and chemical engineering, it is suitable for large-scale industrial powder production, including coal powder preparation, slag micro powder, and non-metallic mineral pulverization (e.g., limestone, barite, marble).

Technical Advantages:

Integrating five functions: crushing, grinding, powder selection, drying, and conveying. It occupies a small area, and features high efficiency, energy conservation, and environmental friendliness.

Operates with full-sealed negative pressure, resulting in low equipment vibration, which meets the environmental protection requirements of modern industrial production.

Can effectively control the particle size and purity of finished products, satisfying the needs of high-quality production.

LUM Ultrafine Vertical Mill

Applicable Fields: Specialized in the coating, plastic, and rubber industries, suitable for the preparation of ultra-fine powders such as calcite, ground calcium carbonate, and talc.

Technical Advantages:

The uniquely designed grinding curves of roller sleeves and liners, combined with a special pre-compaction device and the material layer grinding principle, ensure high grinding efficiency and excellent finished product quality.

Adopting ultra-fine grinding, multi-head powder selection, and an intelligent control system, it features advanced powder selection technology, high efficiency, and energy conservation.

The grinding rollers do not directly contact the grinding disc; high-quality materials are used, and the grinding rollers can be flipped out of the machine shell for maintenance.

XZM Ultrafine Mill

Applicable Fields: Production of ultra-fine powders from non-metallic minerals such as calcite, talc, and barite, used in papermaking and chemical industries.

Technical Advantages:

Under the same fineness and power conditions, its output is 40% higher than that of jet mills, with energy consumption reduced by 20%.

The fineness of finished products can be adjusted from 325 to 2500 meshes, and it can reach the standard of d97≤5μm in one pass.

Equipped with a high-efficiency pulse dust collector and muffler, ensuring no dust pollution or noise pollution during operation.

MTM Medium-Speed Trapezium Grinding Mill

Applicable Fields: An industrial grinding mill developed through elaborate design, testing, and improvement, incorporating the current advanced industrial grinding technology.

Technical Advantages:

Adopting a high-efficiency impeller fan, which increases the air induction efficiency from 62% to 85%.

Equipped with a modular impeller adjustment device, enabling the production of products with different fineness by simply replacing the impeller.

It forms an independent production system from bulk materials to finished powder, resulting in low one-time investment in factory buildings and infrastructure.

LM-Y Vertical Pre-Grinding Mill

Applicable Fields: Mainly suitable for pre-sand-powder preparation processes before crushing mineral materials in industries such as metallurgy, building materials, chemicals, and mining.

Technical Advantages:

Realizes the ideal preparation of high-quality graded sand for special mortar.

Integrates both fine crushing (sand making) and grinding functions, capable of producing finished sand and powder with different gradations as needed.

The equipment system is simple with a compact layout and small footprint, reducing the investment cost of factory construction.