In recent years, driven by the escalating global demand for food security and the dual carbon goals, the phosphate fertilizer industry has witnessed an upsurge in technological innovation and equipment upgrading. As a core process in phosphate fertilizer production, grinding lines are achieving triple improvements in efficiency, quality and environmental benefits through intelligent transformation, breakthroughs in low-grade resource utilization, and the iteration of energy-efficient equipment, thereby injecting strong impetus into the sustainable development of agriculture.

Addressing the Challenge of Low-grade Phosphate Ore Utilization: Pretreatment Process Upgrading Becomes the Key

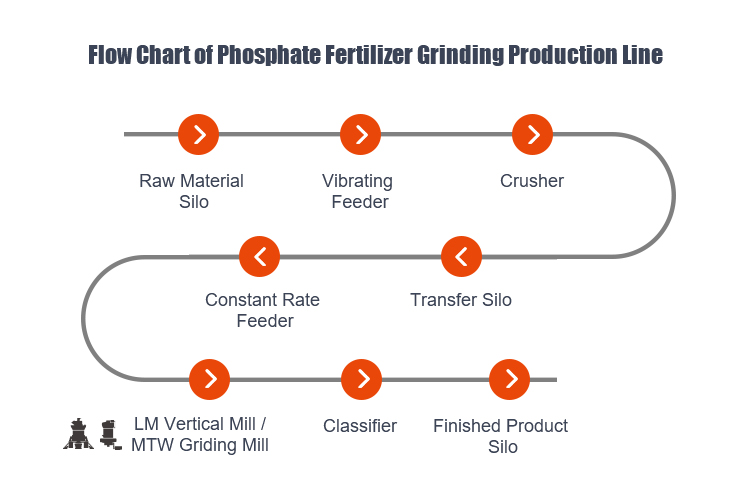

Phosphate ore boasts abundant reserves but exhibits inconsistent grades. Traditional production lines struggle to efficiently process such raw materials due to difficulties in controlling grinding fineness and the lack of beneficiation systems. Targeting the core pain points of phosphate fertilizer grinding, Zenith, with years of intensive experience in the mineral processing sector, has developed customized complete phosphate fertilizer grinding lines tailored to the characteristics of phosphate ore. Through full-process optimization from pretreatment to finished product collection, the solution enables value increment of low-grade ore, high-capacity output and green production. To date, Zenith has helped over 20 phosphate chemical enterprises break through processing bottlenecks and seize industry dividends.

Dual Drivers of Intelligent Transformation and Equipment Iteration: Significant Improvement in Production Capacity and Efficiency

After three months of technological intensive work, a large-scale phosphoric acid plant completed the upgrading and transformation of its grinding equipment. It replaced the original 3m×7m ball mill with a MTW European Trapezium Mill, and optimized the supporting crushing line equipment, achieving a qualitative leap in production efficiency. After the technical transformation, the output per shift surged from 300 tons to 650–700 tons, with an additional daily output of about 100 tons of pure phosphorus. This not only meets the plant’s own phosphoric acid production demand, but also provides stable raw material support for the downstream ammonium phosphate industry.

MTW European Trapezium Mill launched by Zenith is equipped with a customized core grinding host and adopts an integral bevel gear transmission structure, which features higher transmission efficiency and more stable operation. Combined with a high-efficiency classifier, its wear-resistant roller surface design significantly reduces maintenance costs and downtime, and has been successfully applied in phosphate ore concentrators.

Accelerated Green Transition: Technological Innovation Balances Ecological and Agricultural Value

Enterprises across the industry are focusing on environmental upgrading, driving the low-carbon transformation of phosphate fertilizer production through the construction of closed-loop systems and the application of pollutant reduction technologies. For the powdered monoammonium phosphate (MAP) renovation project of Phosphorus Mine & Fertilizer, a large state-owned group, the production system featuring Zenith LM Vertical Mills was adopted. By streamlining the production process and building an innovative closed-loop circulation system, the new equipment achieves independent operation, which significantly improves production flexibility and operational efficiency, while reducing equipment maintenance costs and pollutant emissions.

As technologies such as big data and industrial internet are deeply integrated with phosphate fertilizer production, grinding lines will be further upgraded toward intelligent parameter optimization and full-process automation in the future. With nearly 40 years of experience in grinding equipment manufacturing, Zenith leverages its MTW European Trapezium Mill and LM Vertical Mill as core products. By precisely controlling key parameters including raw material ratio and grinding fineness, Zenith is driving the phosphate fertilizer industry to embark on a new journey of high-quality green development while safeguarding food security.