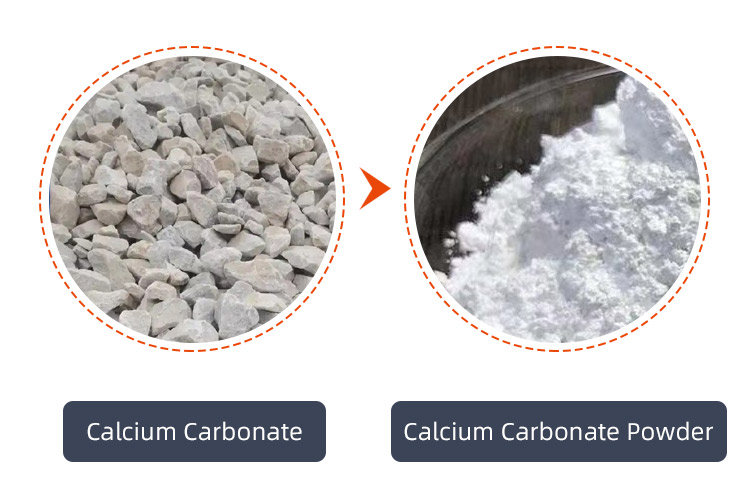

Beneath Iran's vast territory lies abundant non-metallic mineral resources, among which calcium carbonate serves as a fundamental raw material for pillar industries such as construction materials, plastics, coatings, and papermaking. The local government has identified the deep processing of calcium carbonate as a key development priority and plans to enhance product added value through technological upgrading.

The limitations of traditional processing technologies have become increasingly prominent. Most local enterprises still use outdated equipment, which is plagued by issues such as high energy consumption, uneven particle size of finished products, and significant fluctuations in production capacity. With the global industrial upgrading, Iran's mining industry is now confronted with dual challenges:

International competitive pressure: The demand for high-end coatings and pharmaceutical-grade calcium carbonate has surged, yet local equipment struggles to stably produce ultra-fine powders with a particle size of 800 mesh or above, resulting in insufficient product competitiveness.

High-value development of the mining industry: The local authorities are vigorously promoting the intensive development of the mining industry, planning to launch multiple mining projects and strictly controlling energy consumption and environmental protection indicators.

Zenith has deeply integrated into the industrial dynamics of Iran with its cutting-edge grinding equipment and systematic services. The successful application of its XZM Ultrafine Mill in Iran's calcium carbonate projects has become a new benchmark for China-Iran industrial cooperation.

In response to Iran's market demand for transformation and upgrading, Zenith, leveraging its profound technological accumulation and highly tailored product solutions, has become a strategic cooperation partner for a large-scale calcium carbonate production project in Iran.

The project focuses on delivering stable, high-quality calcium carbonate products with a particle size of 800 mesh to Iran's industrial sector. Amidst strict international bidding and selection, Zenith XZM Ultrafine Mill solution successfully stood out with strong advantages.

The project features complex operating conditions, as its raw material characteristics, plant spatial layout, and power supply capacity all differ from those in China. Prior to the project launch, Zenith's technical team conducted thorough research and meticulously documented information such as raw material hardness, initial fineness, and site spatial dimensions.

Through scientific calculations of key parameters—including grinding roller pressure, fan feeding air speed, and classifier rotation speed—Zenith achieved in-depth customized adjustments to the XZM Ultrafine Mill.

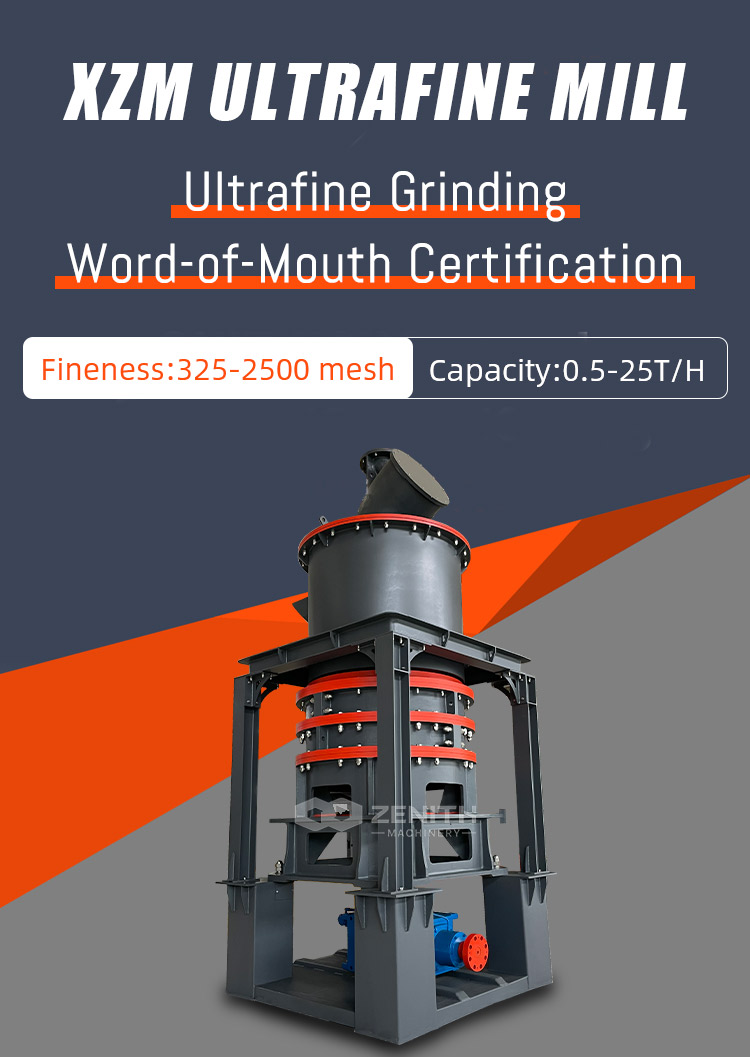

Advantages of XZM Ultrafine Mill

High Efficiency & Energy Savings: Under the same fineness and power conditions, the XZM Ultrafine Mill has a grinding efficiency 40% higher than that of jet mills and agitator mills, while its energy consumption is reduced by 70%.

Precise Particle Size Control: Equipped with a new-type high-efficiency cage separator and frequency conversion control, it enables easy particle size adjustment and accurate cut size. The final fineness of the finished product can reach d97 ≤ 5μm in one pass.

Safe & Reliable Operation: There are no rolling bearings or screws inside the grinding chamber, which avoids problems such as easy bearing damage and equipment failure caused by loose screws.

Clean & Environmentally Friendly: It adopts a high-efficiency pulse dust collector, and is equipped with a silencer and a soundproof room. This reduces dust and noise pollution, far exceeding the requirements specified in national standards.

Zenith provides customers with a complete project implementation solution. After the entire set of equipment was delivered to Iran, Zenith's engineering team responded quickly to deploy the equipment installation task, ensuring the accurate positioning of core equipment.

During the commissioning phase, the entire process was closely aligned with the actual on-site conditions in Iran, and all procedures met the project execution timeline. This successfully earned the customer's high trust and sincere recognition.

With nearly 40 years of technical expertise in the calcium carbonate industry, Zenith has broken free from the traditional positioning of an equipment supplier by leveraging its accumulated technical strength. It has transformed into a "Total-Lifecycle Solution Provider for Calcium Carbonate Powder Engineering" and built an innovation system. Based on advanced technologies, Zenith has developed full-lifecycle service capabilities covering raw material testing, process design, equipment manufacturing, installation and commissioning, and after-sales service.