Expansion of Barite Application Fields

As a mineral for strategic emerging industries, barite has seen continuous expansion of its application fields in recent years with technological advancements. It has expanded from traditional sectors such as chemical engineering, petroleum, construction materials, and medicine to emerging fields like new energy and new materials.

Barite, as a sulfate mineral of barium, has barium sulfate (BaSO₄) as its core component. It is classified as an important non - renewable non - metallic raw material mineral, but with the deepening of its development and utilization, this status is gradually shifting to scarcity. Against this backdrop, improving its development and utilization potential as well as comprehensive utilization efficiency is of great strategic significance for ensuring the security of barite resources.

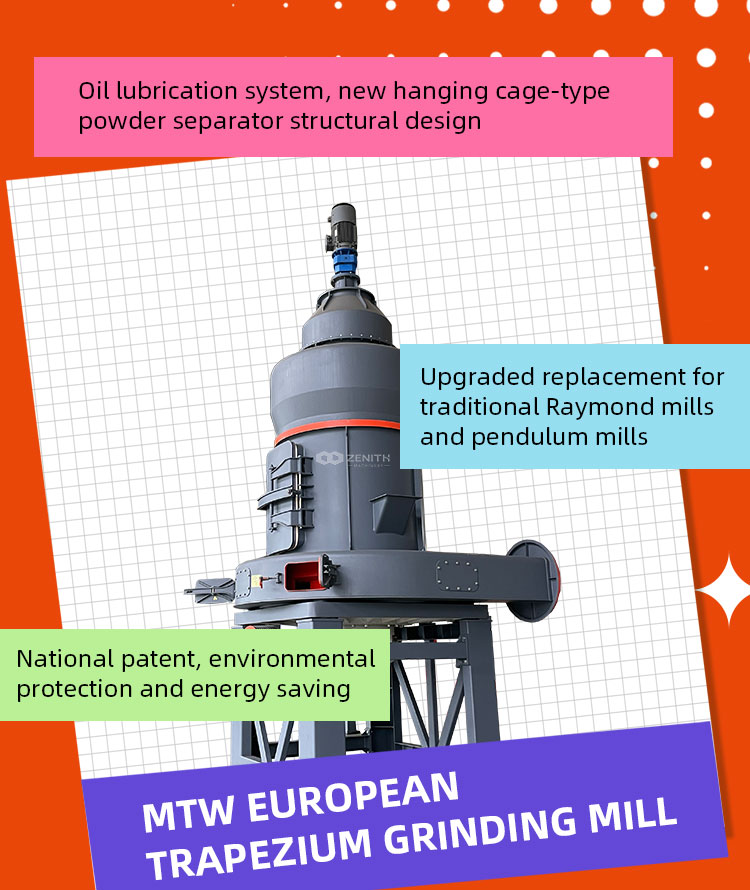

This barite powder production line takes the MTW European trapezium grinding mill as the core main equipment. From the project planning stage, Shanghai Zenith scientifically designed the production line layout according to site conditions and production requirements. The entire production line closely connects links such as crushing, powder grinding, classification, and conveying, achieving process continuity and efficiency. In terms of intelligence, the production line is equipped with an advanced control system, which can monitor the equipment operation status in real time, precisely adjust production parameters, and ensure stable and efficient production processes.

The project production manager feedback: "Over the years, we have always chosen your grinding equipment because of the consistent quality. MTW European trapezium grinding mill can be said to be a capable assistant on our enterprise development path, overcoming obstacles together with us and helping us secure more and more orders!"

Advantages of MTW European trapezium grinding mill

01 Innovative Design to Reduce Investment Costs

MTW European trapezium grinding mill adopts a unique structural design that integrates multiple functions, featuring a small footprint to effectively reduce workshop construction costs. Its modular design facilitates installation and transportation, further lowering initial project investment. Meanwhile, the equipment operates stably and reliably with a long maintenance cycle, significantly reducing later-stage maintenance costs.

02 High-efficiency Grinding to Ensure Product Quality

The grinding rolls and discs of MTW European trapezium grinding mill are manufactured from special materials and processes, significantly improving grinding efficiency. By optimizing the powder selection system, it can precisely control the particle size of the finished product. The produced barite powder features uniform particle size and high purity, meeting the strict requirements of different industries for barite powder and helping customers explore high-end markets.

03 Stable Operation to Improve Production Efficiency

Equipped with advanced shock absorption devices and overload protection systems, the equipment effectively reduces vibration and noise during operation, ensuring long-term stable operation and improving production efficiency.

04 Intelligent Control for Convenient Management

MTW European trapezium grinding mill is equipped with an intelligent control system, allowing operators to remotely monitor equipment operation data in real time through a remote monitoring platform and adjust the production process remotely. The system has a fault early warning function, which can timely detect and solve potential problems, reducing downtime and improving management efficiency.

05 Green and Environmentally Friendly to Fulfill Social Responsibilities

Shanghai Zenith always integrates environmental protection concepts into product design and production processes. MTW European trapezium grinding mill is equipped with an efficient dust collection system to effectively reduce environmental pollution. Meanwhile, the equipment has low operating energy consumption, helping enterprises achieve green and sustainable development.

In the current context of a continuously heating up barite market and strong demand, Shanghai Zenith, in response to the characteristics of barite resources and market application needs, will continue to commit to grinding technology innovation and equipment R&D. This aims to achieve in-depth development and utilization of barite resources, assist the industry in transforming and upgrading from extensive development to refined, green, and intelligent development, and promote the industry towards high-quality sustainable development.