In an era where global manufacturing is accelerating its transformation from "traditional manufacturing" to "intelligent manufacturing", intelligent manufacturing and digital transformation have emerged as definitive development imperatives. Shanghai Zenith has established itself as a leading authority in the field of grinding equipment and technology. Upholding a philosophy of "crafting excellence through ingenuity" and driving corporate advancement via technological innovation, the company has now embarked on a new chapter of "upgraded transformation" in intelligent manufacturing. This journey embodies a distinctive development pathway in intelligent manufacturing that uniquely integrates Zenith technical expertise, industrial insights, and innovative capabilities.

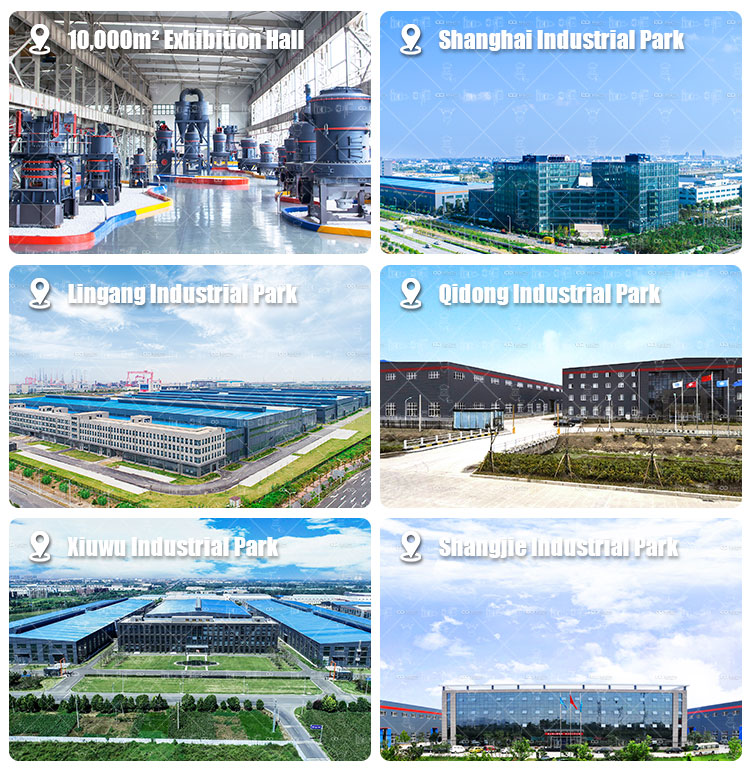

Expansion of Production Bases

Since its establishment, Shanghai Zenith has remained dedicated to technological R&D and equipment manufacturing in the industrial powder processing sector. The company has established six modern production clusters centered in Zhengzhou and Shanghai, further enhancing its locational, technological, manufacturing, and service advantages—injecting strong new momentum into its long-term development. Meanwhile, Shanghai Zenith continuously optimizes production processes and improves operational efficiency, ensuring product quality and reliability through rigorous quality control systems.

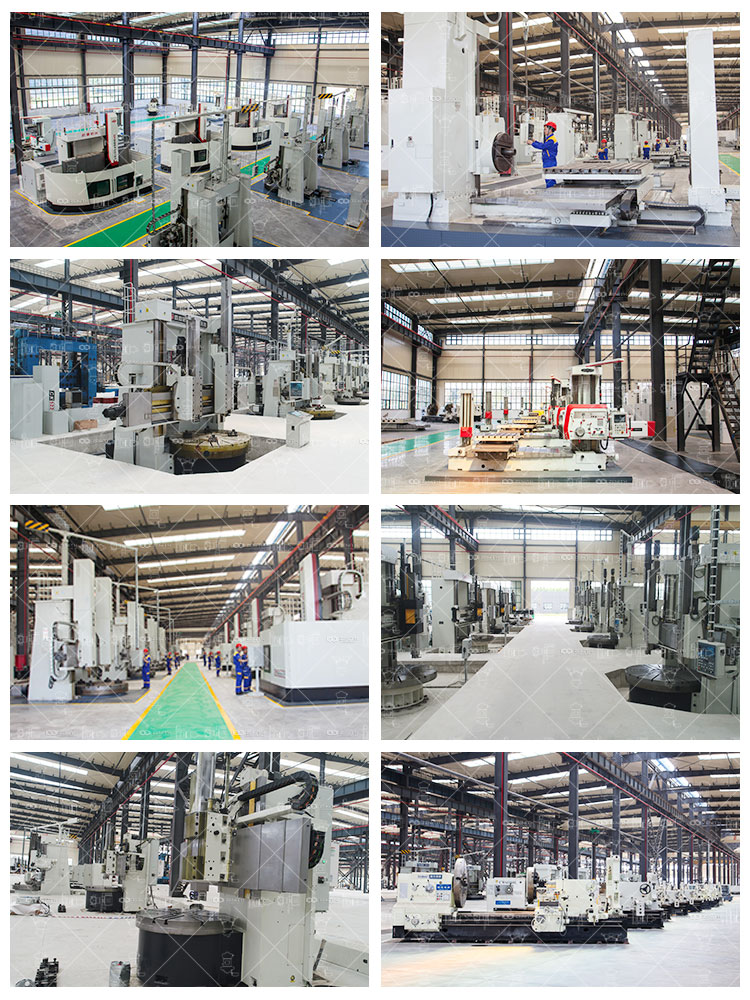

Seiko Manufacturing Powerhouse

Shanghai Zenith drives industrial upgrading through innovation, deeply integrating artificial intelligence, big data, and IoT technologies to create an intelligent production system. By implementing full-process data control through a digital platform, it significantly enhances production efficiency and quality levels, propelling the manufacturing industry toward automation and high efficiency.

There are more than 1,000 sets of precision manufacturing instruments, such as laser cutting machines, plasma cutting machines, CO₂ gas shielded welding machines, vibration aging instruments, 800T hydraulic bending machines, double-sided CNC horizontal milling and boring machines, CNC floor boring and milling machines, 5-meter CNC double-column vertical lathes, 6.3-meter CNC double-column vertical lathes, semi-automated assembly lines, metallographic analysis equipment, coordinate measuring machines, etc. These ensure that every link from batching, welding, machining to equipment installation, painting, and packaging can achieve the highest standards of precision and excellence.

Integrated Solutions for Grinding Equipment

Taking the manufacturing of high-quality and high-efficiency grinding equipment as its core, Shanghai Zenith has established a full industrial chain system from R&D to manufacturing. The company actively participates in industry summits in new energy, new materials, non-ferrous metals, calcium-based industries, etc., and continues to carry out on-site visits through the "Quality China Tour," going deep into production sites to identify pain points in equipment operation. By collecting problems, conducting technical reviews, and optimizing processes, it continuously promotes product upgrades to provide customers with more reliable solutions.

Shanghai Zenith Global Footprint and Commitment

Based in the global market, Shanghai Zenith service network covers more than 180 countries and regions, having provided efficient technical support to over 30,000 customers. Relying on hundreds of regional service centers and a digital operation and maintenance system, the company has earned customer trust through rapid response and professional services, injecting Chinese wisdom into global industrial development.

Upholding the mission of revitalizing national industry and building a century-old brand, Shanghai Zenith takes quality as its foundation and drives development through innovation. With its strong development resilience and leading role in the industrial chain, it continues to redefine the quality standards and technological heights of Chinese manufacturing.