Language

Language

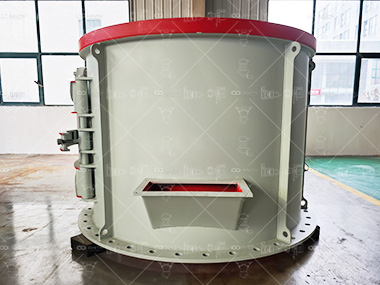

PMD New Generation Permanent-Magnet Direct Drive Intelligent European Trapezium Mill makes its spectacular debut, pioneering a new trend of technological upgrading in the grinding mill industry.

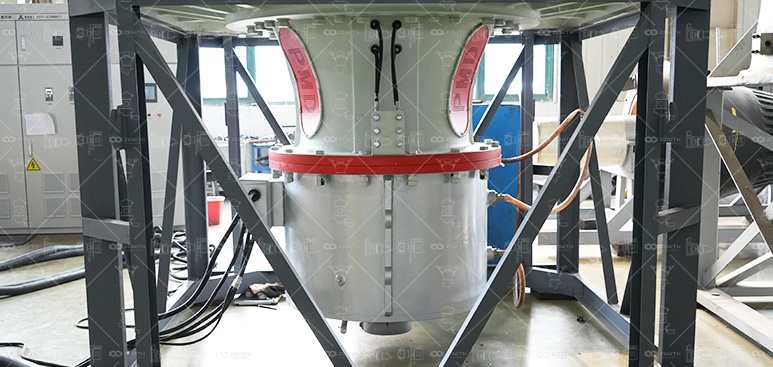

This innovative model takes the lead in applying the permanent magnet direct drive motor to the pendulum grinding mill field, breaking the limitations of traditional transmission modes in one fell swoop and achieving seamless integration of the power system and intelligent control.

Leveraging the advantages of permanent magnet direct drive technology, the equipment delivers stronger and more stable power output, ensures more reliable operation of transmission components, significantly reduces system energy consumption, and simultaneously improves grinding efficiency and equipment service life.

Compared with traditional Raymond mills, its energy efficiency jumps by 30%, helping enterprises drastically cut down production and operation costs and gain higher economic benefits.

Capacity: 6-55T/H

Input Size: 35-50mm

Output Size: 0.038-1.6mm

Product Data Download

Product Data Download

Delivers strong and stable power output, upgrades equipment reliability, achieves 15% overall energy saving, and realizes cost reduction & efficiency improvement in one step.

Built-in intelligent lubrication system enables real-time online lubrication for the classifier, main unit and all motors. No shut-down for maintenance is needed, supporting enterprises to achieve continuous production and realize more efficient cost reduction and efficiency improvement.

The classifier is upgraded with an innovative structure, optimized in both sealing performance and air flow rate. It directly boosts classification efficiency and precision, facilitating the production of high-quality powder.

The system comes with a brand-new high-performance fan, which directly increases pneumatic energy efficiency by 15%. Compared with traditional fans, it also cuts electricity costs by 8%-10%, achieving cost reduction and efficiency improvement in one step.

Materials qualified after crushing are uniformly, quantitatively and continuously conveyed to the grinding chamber of the main unit by a variable-frequency belt feeder for grinding. The ground materials are driven by the air flow of the fan and conveyed to the classifier for particle size classification. Driven by the classification system, materials that fail to meet the fineness requirements fall back into the grinding chamber for regrinding, while qualified powder is carried by the air flow through pipelines into the cyclone powder collector for gas-solid separation and collection, and finally discharged through the discharge mechanism as finished products.

The separated air flow returns to the fan through the air return pipe at the top of the cyclone powder collector, forming a closed-loop air flow circuit. The entire system operates in a negative pressure mode and is equipped with a pulse dust collector, with all emission indicators complying with national environmental protection standards.

Fill your requirements in the following form, we will contact you as soon as possible.