What is Kaolin?

Kaolin is a clay mineral, part of the group of industrial minerals with the chemical composition Al2Si2O5(OH)4. It is a layered silicate mineral, with one tetrahedral sheet of silica (SiO4) linked through oxygen atoms to one octahedral sheet of alumina (AlO6) octahedra. Rocks that are rich in kaolinite are known as kaolin or china clay.

| CHEMICAL CLASSIFICATION |

SILICATE |

| COLOR |

WHITE(MAX WHITENESS>95%), INCANUS, LUTESCENT |

| PLASTICITY |

GOOD MOLDING, DRYING AND SINTERING PROPERTIES |

| DISPERSITY |

EASY DISPERSION AND SUSPENSION |

| ELECTRICAL INSULATING PROPERTY |

200 ℃, ELECTRICAL RESISTIVITY>1010Ω*CM, |

| CHEMICAL STABILITY |

VERY GOOD, BASAL, PRISMATIC |

| MOHS HARDNESS |

2-2.5 |

| SPECIFIC GRAVITY |

2.609G/CM3 |

Online Chat

Inquiry

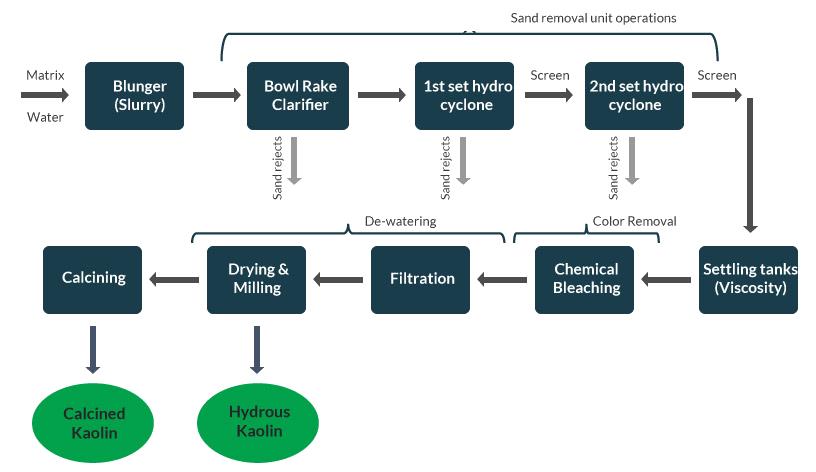

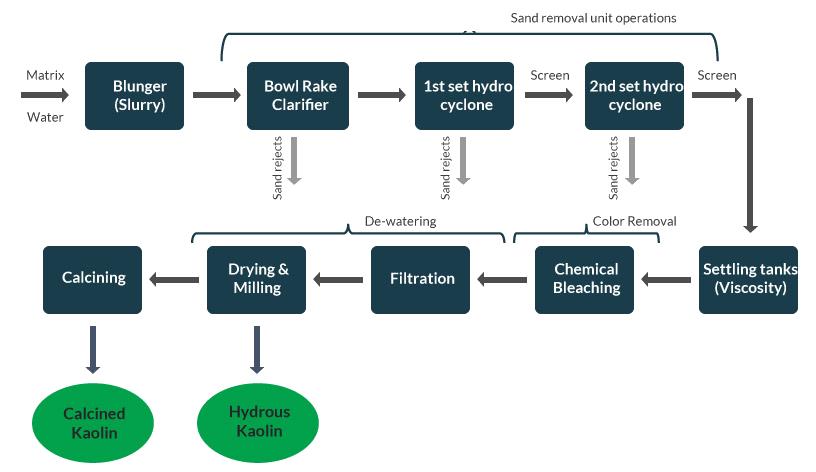

Processing Technology

Typically, presence of iron imparts a pink colour to the matrix. The mined and sorted kaolin is then subject to processing by a wet route to produce processed kaolin with desired properties for various applications.

Recommended Products

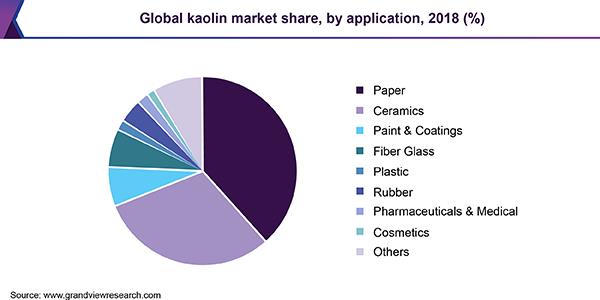

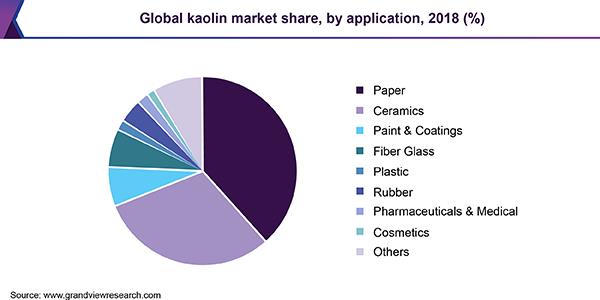

Uses of Kaolin

Reference Project

13T/H Kaolin Powder Production Line in Iran

Location: Iran

Machine: 1 Set MTM130 Grinding Mill

Output Size: 100 Mesh D80

Capacity: 13T/H

15T/H Kaolin Powder Production Line in China

Location: China

Machine: 1 Set MTW175 Grinding Mill

Output Size: 75 Micron D90

Capacity: 15T/H

10T/H Kaolin Powder Production Line in China

Location: China

Machine: 1 Set MTW138 Grinding Mill

Output Size: 100 Mesh D90

Capacity: 10T/H

0086-21-58386256

0086-21-58386256