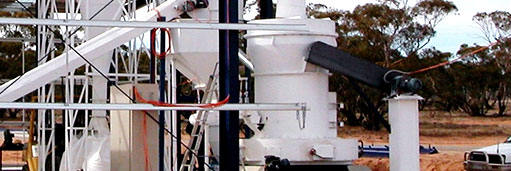

MTW Series Trapezium Mill

They adopt bevel gear integral transmission, inner light-oil lubrication, arc whirl tube and another proprietary technology.

Stable performance, convenient operation, low energy consumption, adjustable and controllable final size, widely used grinding materials , equipped with special dust collector, and dust emission concentration is lower than the national environmental regulations completely.

The working principle is for vertical structure, covering a small area, complete and strong set, and motor transmission device enclosed gear box, with smooth transmission. An important part of the mill adopts high-quality steel manufacturing, so it is reliable and durable. Electrical system of the mill adopts centralized control, advanced and reasonable selection, automation with high degree, vibrating feeder with small size light weight, it is easy to adjust and save electricity.

MTM Series Medium Speed Trapezium Mill

It adopts five mill patent technology , such as the trapezoidal face, flexible connection and roller linkage supercharging.

It solves the leakage phenomenon when grinding the calcium carbonate, improves the grinding efficiency, eliminates the impact on the main shaft, prolonging the service life of the roller shaft, greatly improves the precision and efficiency of selecting powder, reduces the transmission between the mill and classifier and eliminates the resonance phenomenon.

This series mills are mainly applied to the powder processing of mineral products in the metallurgy, construction material, chemical, mining, the highway construction, water conservancy and hydropower, refractory materials, and steel, etc.

How MuchRaymond mill

This series mills are mainly applied in the metallurgy, construction material, chemical, and mining, etc.

The working principle is that by the shovel blade ,calcium carbonate is put to the middle of calcium grinding roller and grinding ring , under the grinding pressure of calcium carbonate is crushed into powder, then under the action of the fan ,the powder of calcium carbonate is passed to analyzer. If the powder calcium carbonate fails to achieves the required fineness by analyzer, it will return to the grinding chamber to continue to grind then through analyzer, calcium carbonate is put into whirlwind powder collector finishing separation and collection. Lastly, with industrial filter cloth isolated exhaust was put into powder at one time. They can produce powder from various non-flammable and non-explosive mineral materials with Mohs hardness below 7.0 and humidity below 6%.

XZM Ultrafine Grinding Mill

For ultrafine calcium carbonate powder production, there is no better choice but XZM ultrafine grinding mill.

Lots of industries need calcium carbonate powder as raw material, such as PVC, Electric Cable, rubber, PE, painting and paper making industries. And many industries like PVC, PE and coating has specified standards to the powder size, usually it must be finer than 1250mesh. As a result, most grinding mills, such as coarse power mill, MTM series milling machine and MTW series grinding mill, are out of action. How to produce the ultrafine calcium carbonate powder? Currently, the mainstream machine is ZENITH XZM series ultrafine grinding mill. With this mill, not only 800-1250mesh powders are available, but also 1250-2500mesh powders are getable. What’s more important is that the production cost is quite low because of its special design.

0086-21-58386256

0086-21-58386256